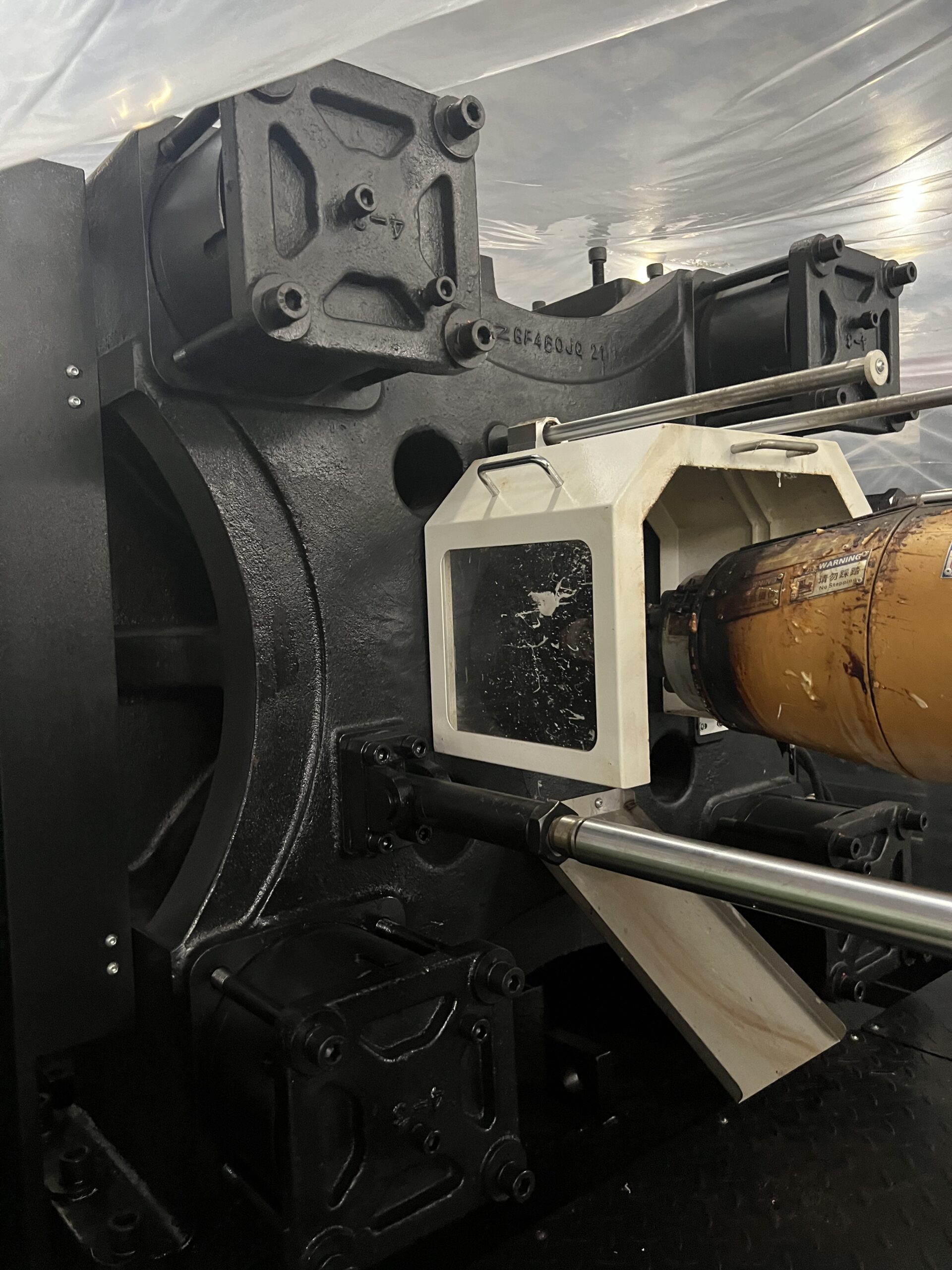

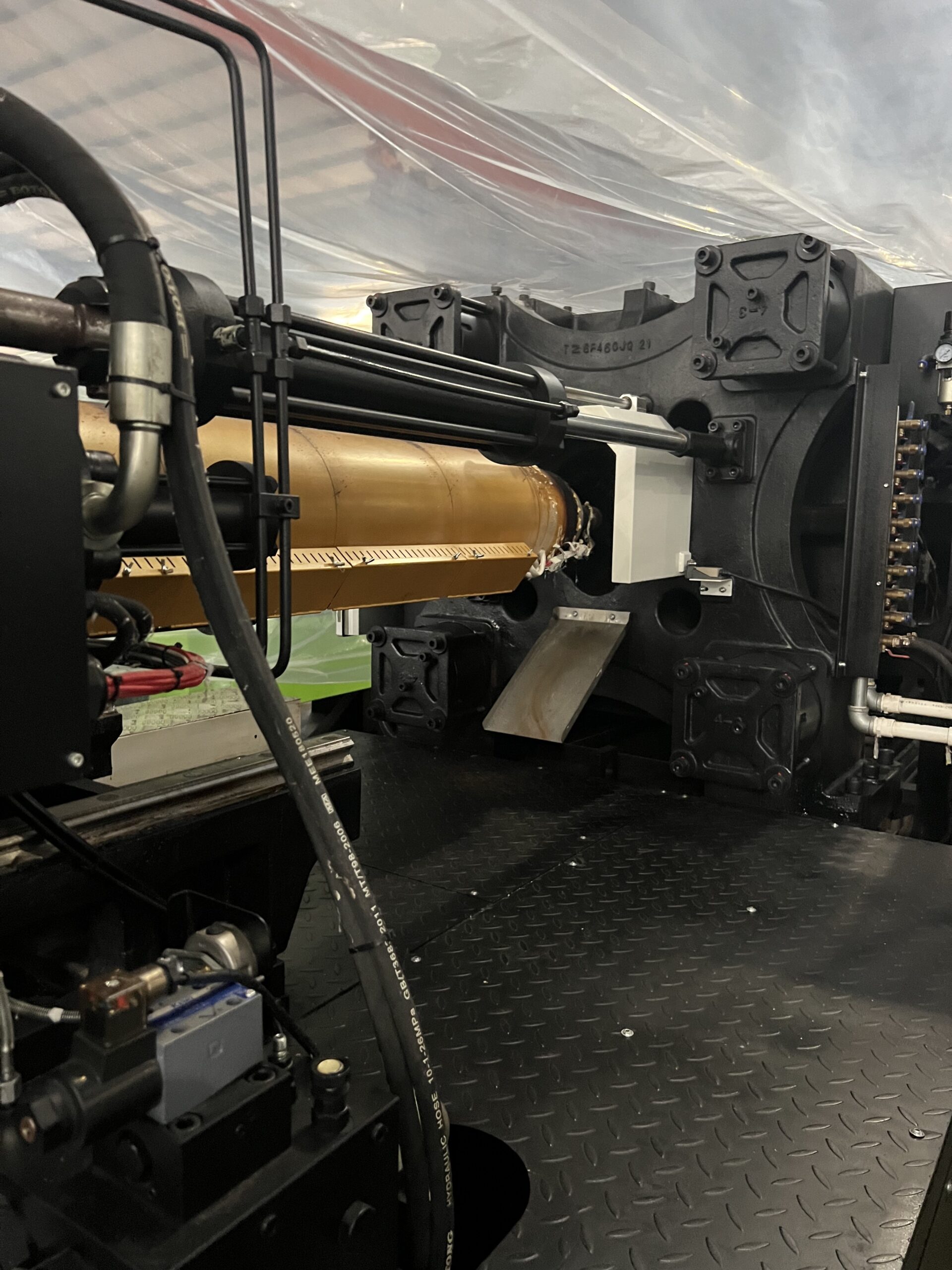

Zhongwei 460T high speed machine

| Specific Parameter Name | Parameter Details |

| Clamping Force | Around 4600 kN, ensuring the tight closure of the mold and guaranteeing the dimensional accuracy and appearance quality of products. |

| Mold Plate Size | The fixed mold plate is approximately square with sides ranging from 1200 mm to 1400 mm, and the moving mold plate is about square with sides from 1100 mm to 1300 mm, adapting to molds of different sizes. |

| Distance between Tie Bars | Usually between 800 mm and 900 mm, which determines the installation space of the mold and the size range of molds that can be accommodated. |

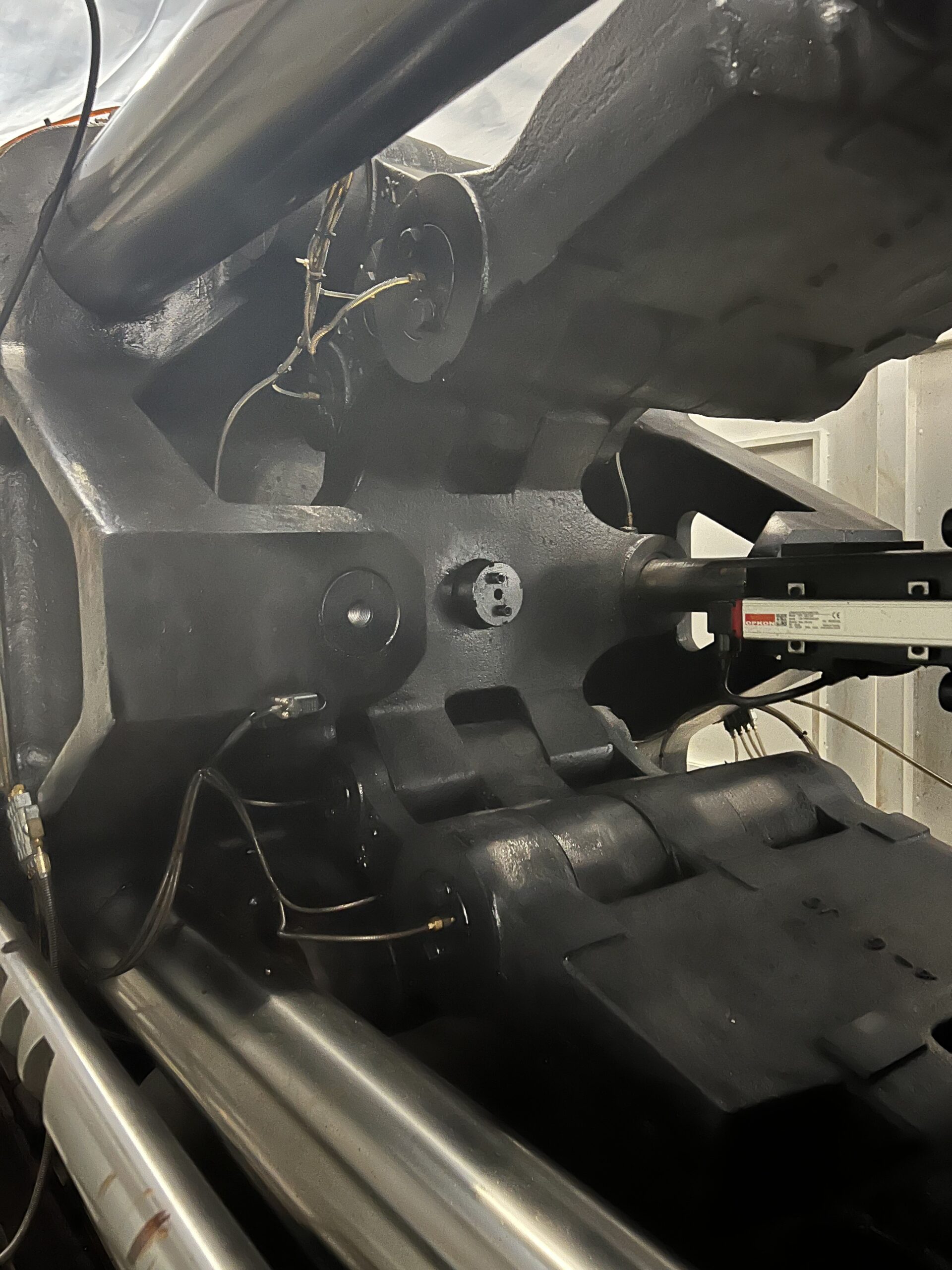

| Mold Opening Stroke | Around 800 mm – 1000 mm, affecting the convenience of product removal, mold cleaning and maintenance operations. |

| Maximum Mold Thickness | Generally reaching around 700 mm – 800 mm, limiting the maximum thickness of the molds that can be used. If the mold thickness exceeds this value, it cannot be installed and used normally. |

| Minimum Mold Thickness | Usually around 300 mm – 400 mm. If it is less than this value, the mold cannot be installed and fixed correctly, thus affecting normal production. |

| Ejector Stroke | Generally around 150 mm – 250 mm. It needs to be adjusted according to the product structure and demolding requirements to ensure smooth demolding. |

| Ejector Force | Around 80 kN – 120 kN, ensuring that the product is reliably ejected during demolding and avoiding remaining inside the mold. |

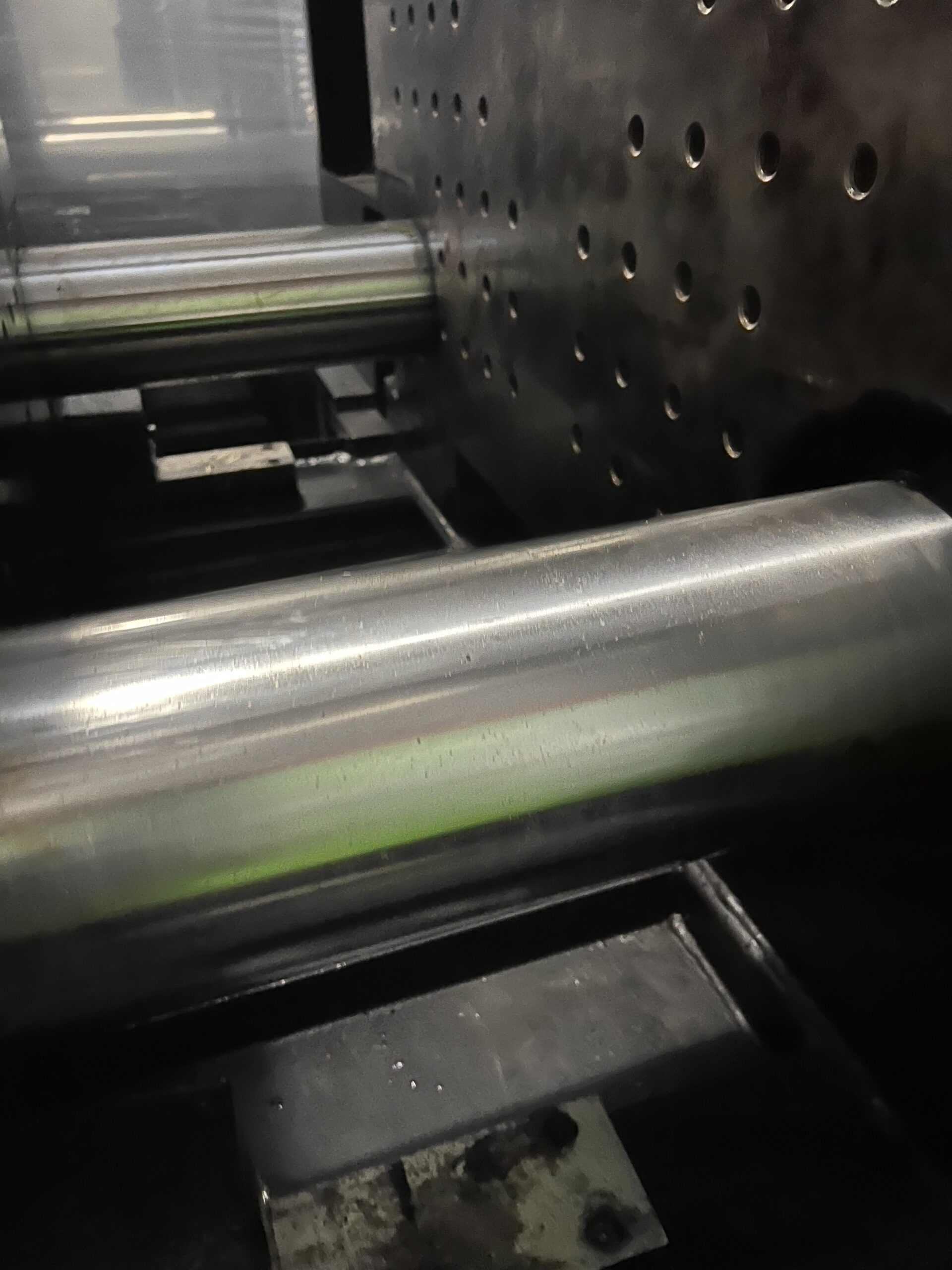

| Screw Diameter | Common specifications include 60 mm and 65 mm, adapting to different plastic raw materials and injection molding product requirements. |

| Screw Length-Diameter Ratio | Generally between 20:1 and 25:1, which affects the plasticizing effect and mixing quality of plastics. |

| Theoretical Injection Volume | When the screw diameter is 60 mm, it is about 700 cm³ – 900 cm³ or so; when the screw diameter is 65 mm, it is about 900 cm³ – 1100 cm³ or so. It determines the volume of plastic injected into the mold each time and affects the size and weight of the product. |

| Injection Pressure | The maximum injection pressure is generally between 180 MPa and 220 MPa, affecting the filling speed and filling effect of plastics in the mold. |

| Injection Speed | Usually adjustable between 100 mm/s and 300 mm/s, affecting the appearance quality, dimensional accuracy and production efficiency of the product. |

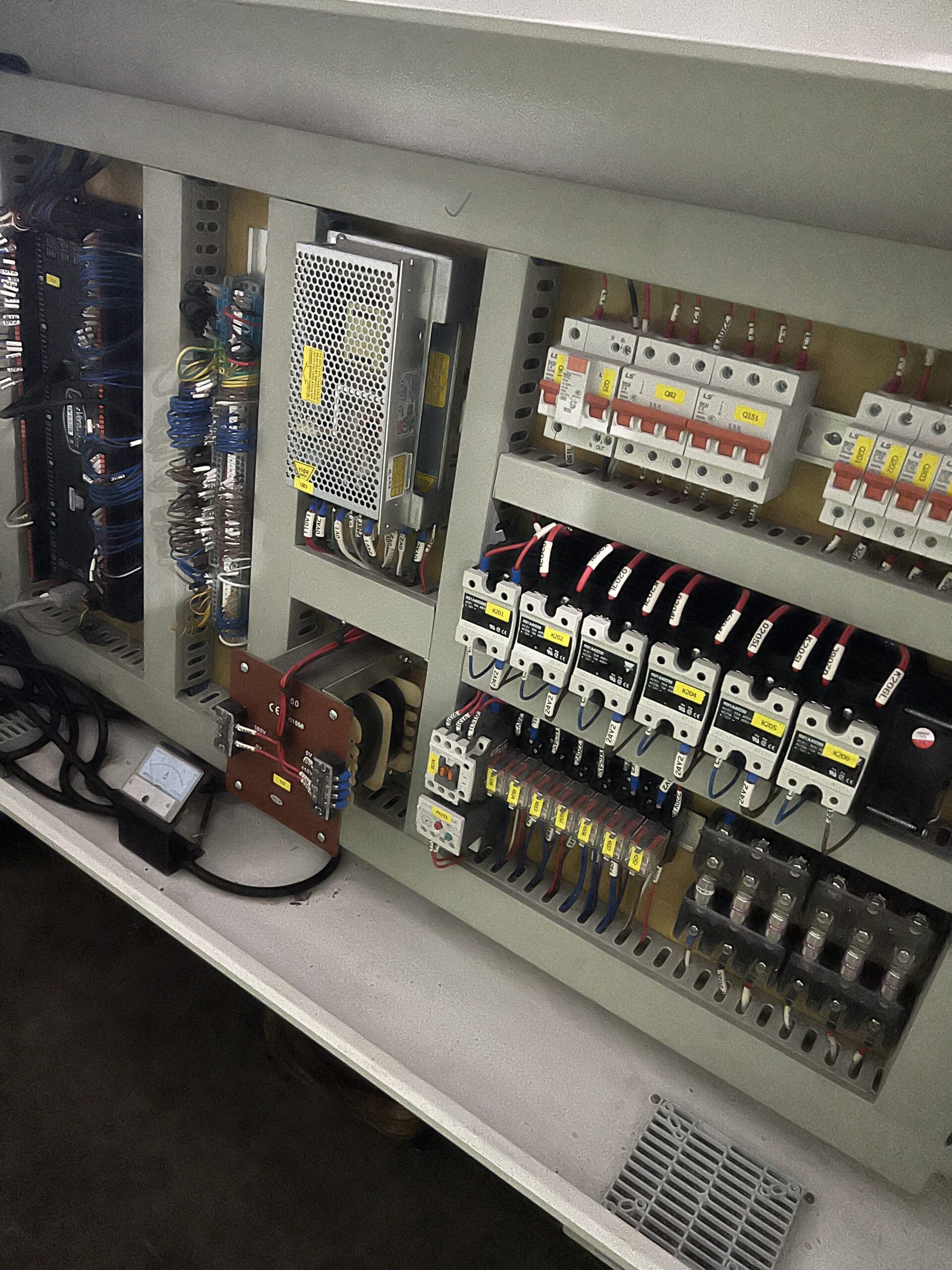

| Heating Power | The total is approximately between 25 kW and 35 kW, which is used to heat the barrel and the mold to ensure the smooth progress of the injection molding process. |

| Motor Power | The power of the main motor is generally between 35 kW and 50 kW, which determines the power output of the injection molding machine and its working efficiency and performance. |

| Overall Dimensions of the Machine | Approximately 7500 mm * 1800 mm * 2200 mm (length * width * height), determining the space required for installation. |

| Weight of the Machine | The whole machine weighs about 25 t – 35 t, affecting the requirements for the installation foundation and the difficulty of transportation. |

Category: Used High Speed Injection Molding

Request a quotation