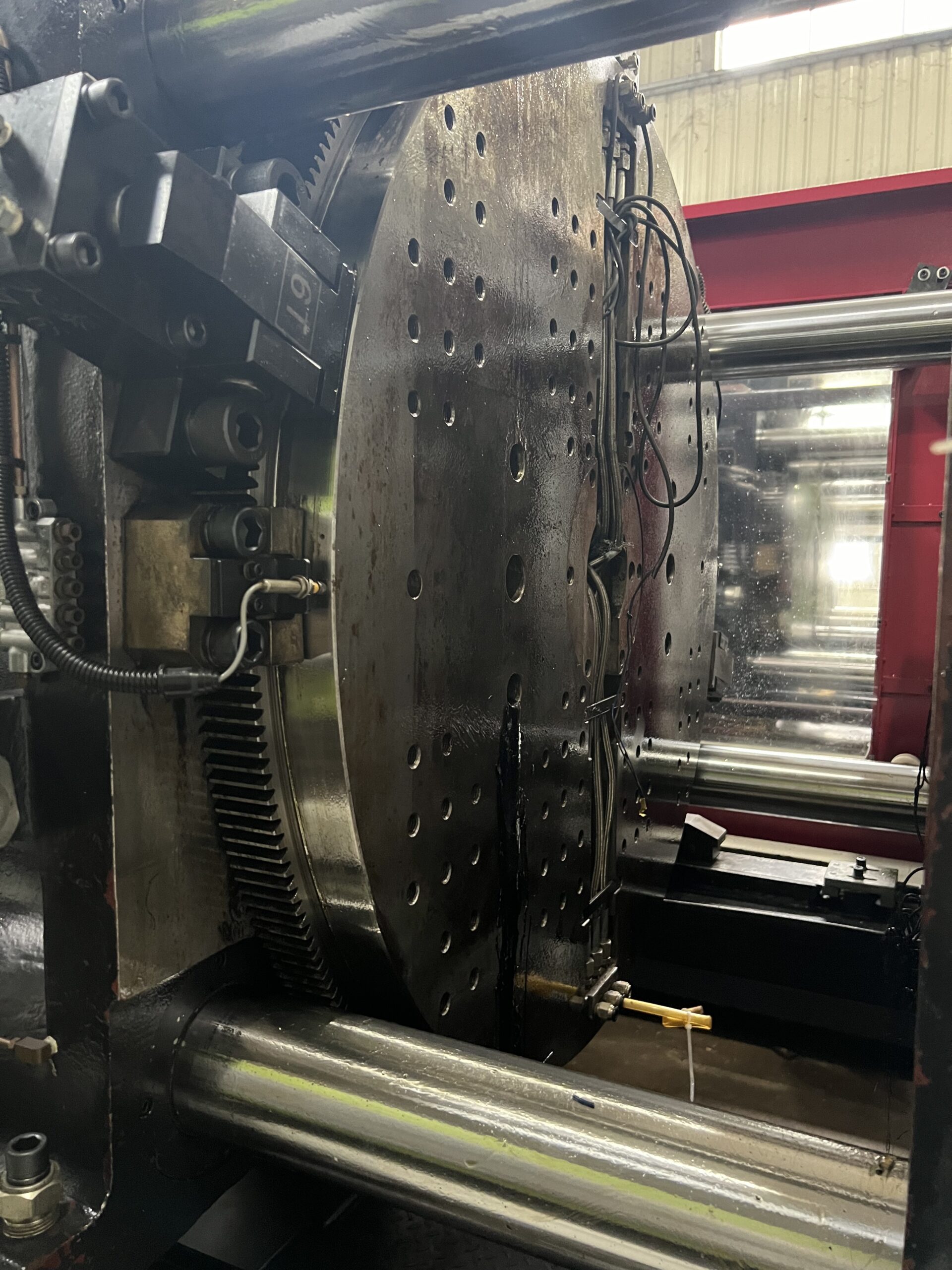

Ramada 270T two-color machine

| Technical Parameter Name | Specific Parameter Details |

| Clamping Force | 2700 kN, which ensures that the mold is tightly closed during injection molding, prevents plastic from overflowing, and guarantees the dimensional accuracy and appearance quality of products. |

| Mold Plate Size | The fixed mold plate is approximately 1100 mm * 1100 mm, and the moving mold plate is about 1000 mm * 1000 mm, adapting to molds of different sizes to meet various production requirements. |

| Distance between Tie Bars | Approximately 700 mm * 700 mm, which determines the installation space of the mold and the size range of molds that can be accommodated. |

| Mold Opening Stroke | About 800 mm – 1000 mm, affecting operations such as product removal, mold cleaning and maintenance. |

| Maximum Mold Thickness | It can reach about 800 mm, limiting the maximum thickness of the molds that can be used. If the mold thickness exceeds this value, it cannot be installed and used. |

| Minimum Mold Thickness | Generally around 300 mm. If it is less than this value, the mold cannot be installed and fixed properly, affecting production. |

| Ejector Stroke | Usually around 200 mm. It needs to be adjusted according to the product structure and demolding requirements to ensure that the product can be smoothly demolded. |

| Ejector Force | About 100 kN, ensuring that the product is reliably ejected during demolding and avoiding remaining in the mold. |

| Screw Diameter | There are commonly available specifications such as 60 mm and 70 mm, adapting to different plastic raw materials and injection molding product requirements. Screws with larger diameters are used for large or thick-walled products. |

| Screw Length-Diameter Ratio | Generally between 20:1 and 25:1, which affects the plasticizing effect and mixing quality of plastics. A larger length-diameter ratio leads to better plasticizing but also increases energy consumption and screw wear. |

| Theoretical Injection Volume | When the screw diameter is 60 mm, it is about 500 cm鲁 or so; when the screw diameter is 70 mm, it is about 700 cm鲁 or so. It determines the volume of plastic injected into the mold each time and affects the size and weight of the product. |

| Injection Pressure | The maximum injection pressure is generally between 180 MPa and 220 MPa, affecting the filling speed and filling effect of plastics in the mold. Appropriate pressure should be selected according to products and materials. |

| Injection Speed | Usually adjustable between 100 mm/s and 300 mm/s, having an important impact on the appearance quality, dimensional accuracy and production efficiency of the product. |

| Mold Closing Speed | The fast mold closing speed is about 200 mm/s – 300 mm/s, and the slow mold closing speed is about 10 mm/s – 30 mm/s. Reasonable settings help to improve efficiency and protect the mold and equipment. |

| Heating Power | The total is approximately between 20 kW and 30 kW, which is used to heat the barrel and the mold to ensure that the plastic can reach the appropriate melting temperature and ensure the smooth progress of the injection molding process. |

| Motor Power | The power of the main motor is generally between 30 kW and 45 kW, which determines the power output of the injection molding machine and affects its working efficiency and performance. |

| Overall Dimensions of the Machine | Approximately 7500 mm * 2000 mm * 2500 mm (length * width * height), determining the space required for installation. It needs to be considered when planning the layout of the workshop. |

| Weight of the Machine | The whole machine is about 25 t – 30 t, affecting the requirements for the installation foundation and the difficulty of transportation. Appropriate methods should be selected according to its weight when installing and moving the injection molding machine. |

Category: Used Two-color machine

Request a quotation